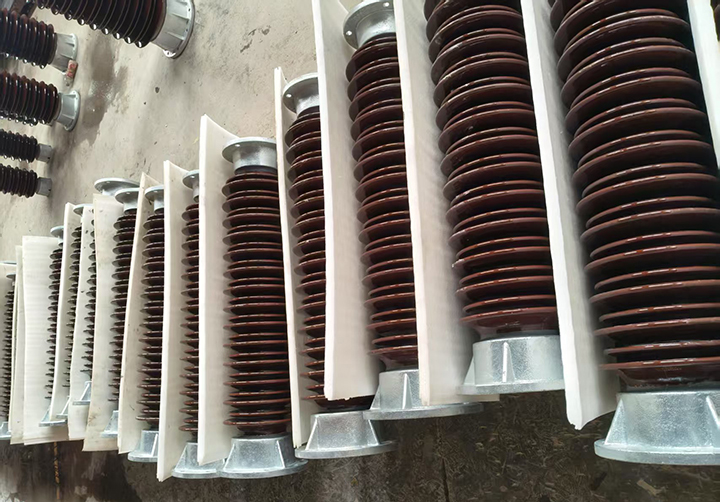

Importance of Seismic Analysis for Porcelain Post Insulators

2025-06-05 07:05Seismic analysis and validation are critically important for porcelain post insulators for several key reasons, primarily stemming from their function, material properties, location, and the severe consequences of failure:

1. Brittle Material Failure

Porcelain is inherently brittle. Unlike ductile materials (like steel) that can bend and yield significantly before failing, porcelain has very low tensile strength and cracks or shatters catastrophically with relatively little deformation when overloaded.

Seismic loads (ground shaking) generate complex, dynamic stresses (bending, torsion, shear). Analysis predicts if these stresses exceed the porcelain's fracture strength.

2. High Center of Gravity & Slender Profile:

Post insulators are tall, slender structures supporting heavy conductors and equipment at the top. This creates a high center of gravity.

During an earthquake, ground acceleration induces significant inertial forces at the top. This creates large bending moments at the base and intermediate flanges/sheds, which are critical stress points.

3. Dynamic Amplification & Resonance:

Structures have natural vibration frequencies. If the frequency content of the earthquake ground motion matches or is close to the insulator's natural frequency, resonance occurs.

Resonance dramatically amplifies the displacements and stresses experienced by the insulator, far exceeding what static analysis would predict. Seismic analysis (especially dynamic analysis) is essential to identify and mitigate this risk.

4. Critical Function in Power Systems:

Post insulators provide vital **electrical insulation** and **mechanical support** for high-voltage busbars, disconnect switches, circuit breakers, and other equipment within substations.

Failure of even a single critical insulator can lead to:

Short Circuits: Collapsing conductors touch grounded structures or other phases.

Cascading Failures: One failure can cause mechanical impact on adjacent equipment.

Major Power Outages: Disrupting power transmission and distribution over wide areas.

Equipment Damage: Expensive damage to transformers, breakers, etc.

Fire and Explosion Hazards: Due to arcing and ruptured equipment (e.g., transformers).

Safety Hazards: For personnel and the public due to falling debris, explosions, and energized equipment on the ground.

5. Grid Resilience & Reliability:

Electrical substations are critical nodes in the power grid. Their ability to withstand earthquakes is paramount for the resilience of the entire power system.

Failure of post insulators is a common cause of substation damage during earthquakes. Seismic qualification ensures the grid can recover faster or potentially remain partially operational after a quake.

6. Compliance with Standards and Regulations:

Building codes (like IBC in the US) and industry standards (like IEEE 693 - Recommended Practice for Seismic Design of Substations) mandate specific levels of seismic performance for electrical equipment, including post insulators.

Utilities often require rigorous seismic qualification (analysis AND testing) as a condition of purchase, especially in high seismic risk zones.

7. Why Validation (Testing) is Crucial Alongside Analysis:

Model Uncertainty: Mathematical models used in analysis involve simplifications and assumptions (e.g., material properties, boundary conditions, damping). Testing validates these models.

Complex Interactions: The dynamic interaction between the insulator, its base, the supported equipment, and the conductors is complex. Full-scale or representative testing captures these interactions better than pure analysis.

Manufacturing Variability: Analysis typically assumes ideal geometry and material. Testing actual production units accounts for manufacturing tolerances and material variations.

Demonstration of Real Performance: Passing a rigorous shake table test according to IEEE 693 or similar standards provides the highest level of confidence that the insulator *as built* will perform as required during an actual earthquake. It proves the design works in reality.

Consequences of Neglecting Seismic Analysis & Validation:

Catastrophic Failures: Unexpected brittle fracture during an earthquake.

Extended Blackouts: Prolonged power outages affecting communities, hospitals, emergency services, and the economy.

Costly Repairs: Replacement of damaged insulators and associated equipment is expensive and time-consuming.

Safety Incidents: Risk to life from falling debris, fires, and electrocution.

Regulatory Non-Compliance: Inability to operate in seismically active regions or failure to meet utility requirements.

In essence, seismic analysis predicts how the porcelain post insulator will behave under earthquake loads and identifies potential weaknesses. Validation (primarily through shake table testing) proves that the insulator can withstand the required seismic demands without failure, ensuring the safety, reliability, and resilience of critical electrical infrastructure. Given the brittle nature of porcelain and the severe consequences of failure, this combined approach is not just important – it's essential.

For Seismic test report, please contact us.